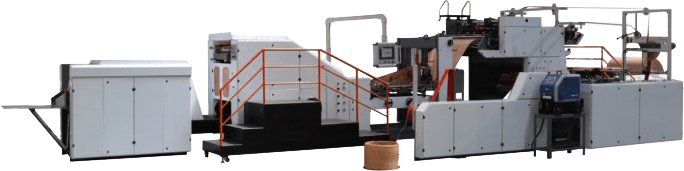

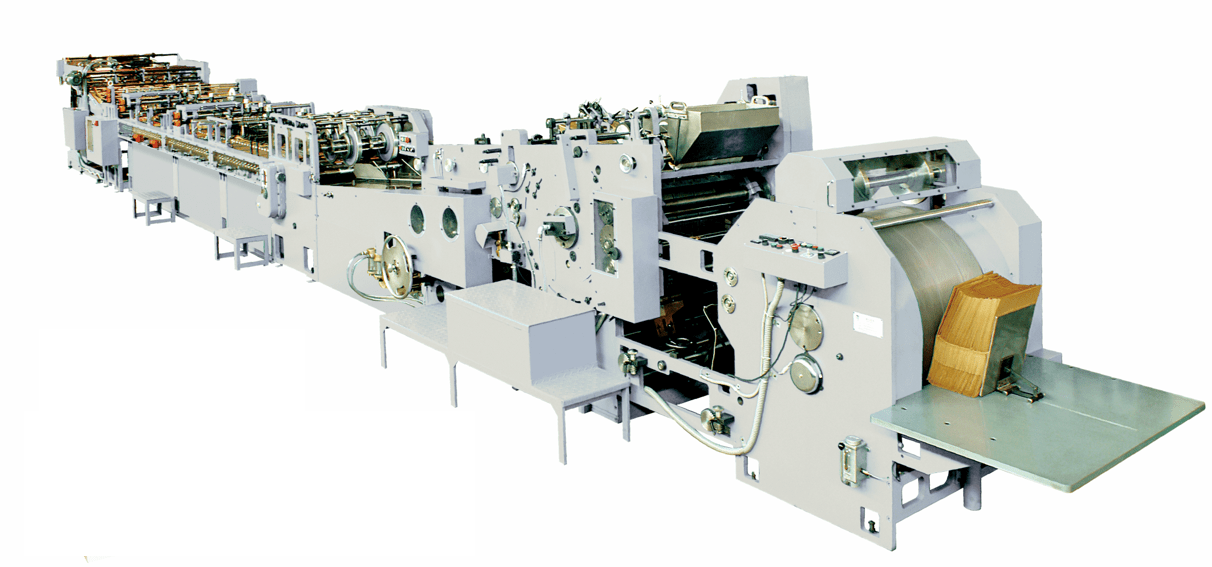

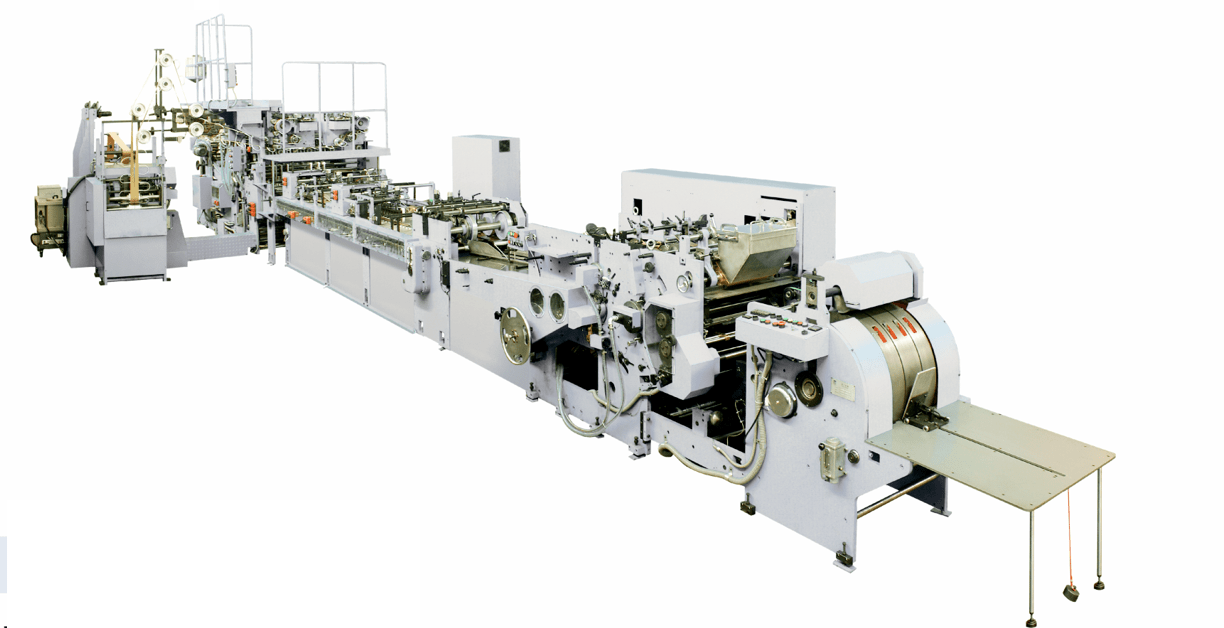

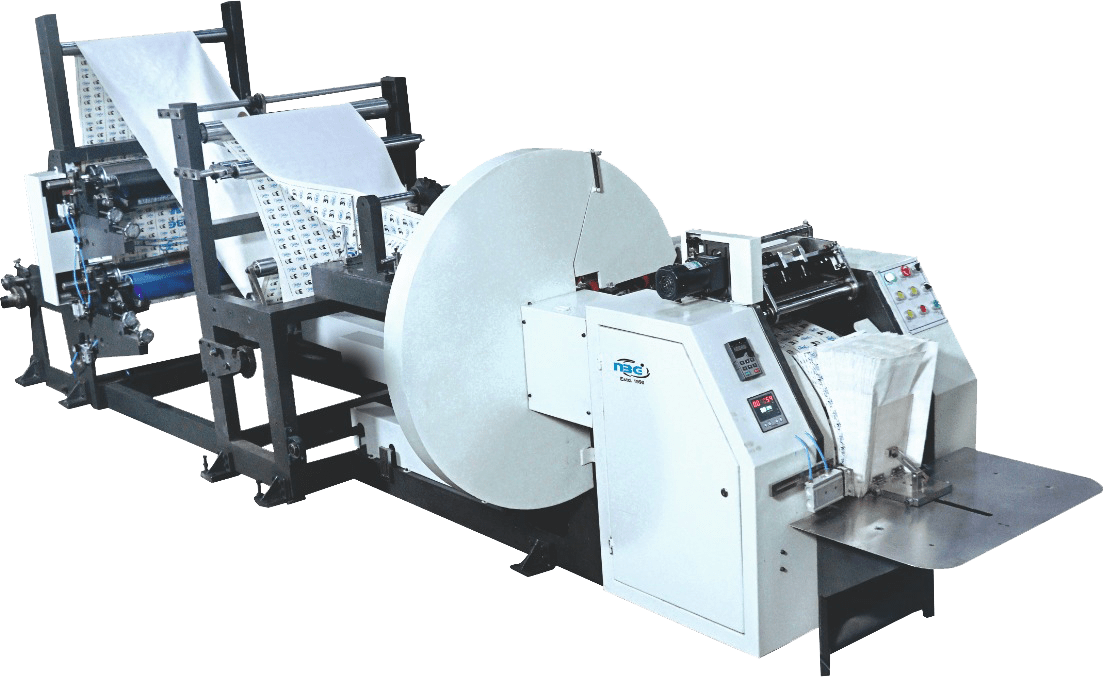

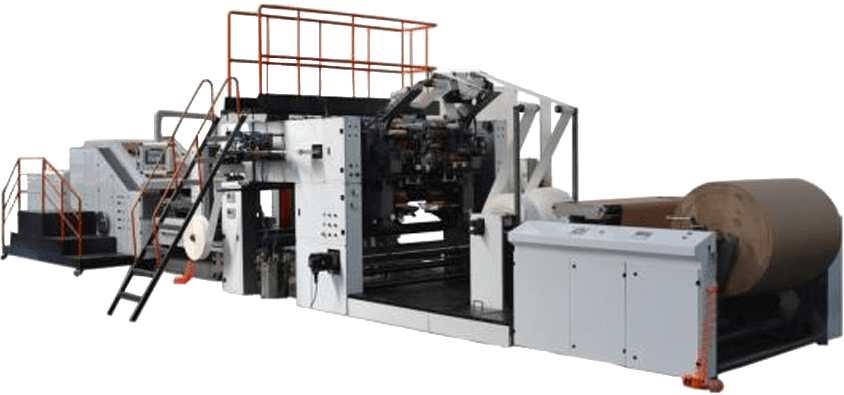

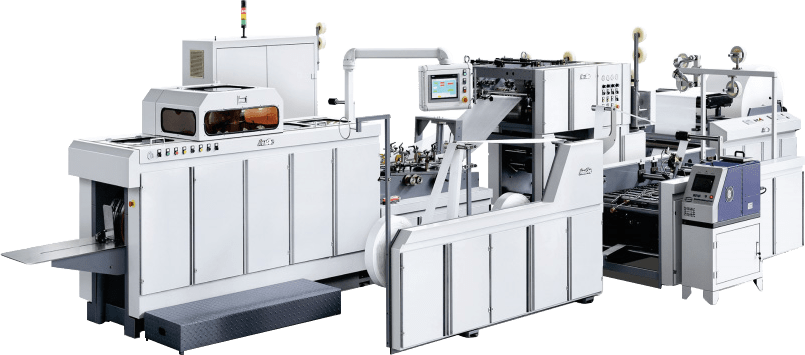

Type of Paper Bag Making Machines

Paper Bag Making Machines Features:

Our paper bag making machines come with a variety of features and functionalities to meet your specific needs. Here are some common features you may find in our machines:

- Paper feeding system: Our reliable and efficient paper feeding system ensures the continuous and accurate feeding of paper into the machine, minimizing downtime.

- Printing capability: Some of our paper bag making machines are equipped with printing units that allow you to print logos, brand names, or other designs on the bags on-the-spot, enhancing your brand awareness.

- Handle attachment: Our machines designed for producing bags with handles have mechanisms to attach handles securely and precisely, depending on your specific requirements (flat handles, twisted handles, loop handles, etc.).

- Gluing and folding units: Our gluing and folding units ensure proper adhesion and crisp folding, resulting in high-quality paper bags.

- Bag forming: Our machines can create various types of bag shapes, including square bottom bags, flat bottom bags, and custom-designed bag shapes, giving you the flexibility to meet your unique needs.

- Adjustment controls: Our machines feature user-friendly adjustment controls, allowing you to customize the bag size, folding style, handle attachment, and glue application to suit your specific requirements.

- Production speed: Our paper bag making machines offer a range of production speeds to meet your needs, from hundreds to thousands of bags per hour, enabling you to achieve high-volume production.

With our paper bag making machines, you can produce high-quality paper bags efficiently and cost-effectively. Contact us today to learn more about our machines and how we can help you achieve your business goals.

Best Paper Bag Making Machines

| Feature | Sharp Bottom (V Bottom) Paper Bag Machine | Automatic Roll Fed Square Bottom Paper Bag Machine With Twisted Handle | Automatic Square Bottom Paper Bag Machine With Flat Handle Over Folded or Upright | Roll Fed Square Bottom Paper Bag Machine | Automatic Square Bottom Paper Bag Machine With Twisted Ropes Flat Handle | Semi Automatic Sheet-Fed Square Bottom Paper Bag Machine |

| Production capacity | 100-200 bags per hour | 300-500 bags per hour | 200-300 bags per hour | 100-200 bags per hour | 300-500 bags per hour | 100-200 bags per hour |

| Paper thickness | 30-150 GSM | 30-150 GSM | 30-150 GSM | 30-150 GSM | 30-150 GSM | 30-150 GSM |

| Bag size | Customizable | Customizable | Customizable | Customizable | Customizable | Customizable |

| Handle type | None | Twisted handle | Flat handle, folded or upright | None | Twisted ropes flat handle | None |

| Printing | Yes | Yes | Yes | No | Yes | No |

| Automation level | Manual | Automatic | Automatic | Manual | Automatic | Semi-automatic |

Importance of Paper Bag Making Machines

Paper bag making machines are important for a variety of reasons. They can help businesses to save time and money, improve efficiency, and produce high-quality bags. They can also help to reduce waste and pollution.

These paper bag-making machines are specially designed to make paper shopping bags with handles inline automatically. The handle will be delivered to the main machine after being produced by the handle-making unit, and being cut and pasted to the paper. Thus it is an ideal equipment for printing houses and paper bag manufacturers.

Benefits of Using Paper Bag Machines

There are many benefits to using paper bag machines. Some of the key benefits include:

Increased productivity: Paper bag machines can help businesses to increase their productivity by automating the production process.

Reduced labour costs: Paper bag machines can help businesses to reduce labour costs by eliminating the need for manual labour.

Improved quality: Paper bag machines can help businesses to improve the quality of their bags by producing consistent, high-quality bags.

Increased versatility: Paper bag machines can be used to produce a variety of bags, which can help businesses to meet the needs of their customers.

How to Choose the Right Paper Bag Making Machine?

Here are some tips on how to choose the right paper bag making machine:

Step 1: Production Needs and Requirements

The first step is to assess your production needs and requirements. How many bags do you need to produce per hour? What size and style of bags do you need? What type of paper will you be using?

Step 2: Budget Considerations

How much are you willing to spend on a paper bag making machine? The price of paper bag making machines can vary widely, depending on the features and capacity.

Step 3: Evaluate Machine Quality and Reliability

It is important to choose a paper bag making machine that is made from high-quality materials and is built to last. You should also consider the machine\'s warranty and service offerings.

Step 4: Read Reviews and Customer Feedback

Reading reviews and customer feedback can be a helpful way to get an idea of how a particular paper bag making machine performs in real-world conditions.

Maintenance and Care for Paper Bag Making Machines

To keep your paper bag making machine running smoothly, it is important to maintain and care for it properly. Here are some tips:

- Regular cleaning and lubrication: This will help to keep your machine running smoothly and prevent wear and tear.

- Troubleshooting common issues: It is important to be familiar with the common issues that can occur with paper bag making machines so that you can troubleshoot them quickly and easily.

- Preventive maintenance tips: There are a number of things you can do to prevent problems with your paper bag making machine, such as regularly inspecting the machine for wear and tear, and replacing worn or damaged parts.

Safety Precautions While Operating Paper Bag Making Machines

To operate a paper bag making machine safely, it is important to follow these safety precautions:

- Training and operator knowledge: All operators of paper bag making machines should be properly trained in the safe operation of the machine.

- Protective gear and equipment: Operators should wear protective gear, such as goggles, gloves, and a dust mask, while operating the machine.

- Emergency procedures: All operators should be familiar with the emergency procedures in case of an accident.

Conclusion

When making a purchase decision, it is important to do your research and compare different machines and suppliers. You can contact us if you have any questions or would like to learn more about our paper bag making machines.

What our client say

ARR Paper Products Pvt Ltd

Bio Friendly Pvt. Ltd.