Technical specifications

Press Models & Speed Option

STAR – 16 (16,000 COPIES PER HOUR)

STAR – 30 (30,000 COPIES PER HOUR)

newssprint (36,000 COPIES PER HOUR)

Cut-off Sizes Available

508 mm (20″), 533 mm (21″), 546 mm (21 ½ “), 560 mm (22″) and 578 mm (22 3/4”). Other Cut-off Sizes are also available.

Web Offset Press Printing Unit

Mono Unit with Integral Reel Stand (U), Stack Unit (S), 3-Colour Satellite (3CS), 2Hi Tower, 3Hi Tower & 4Hi Tower.

- Key / Screw type / Lever style swing down ink fountain system

- Dynamically balanced plate and blanket cylinders (Chrome Plated/Solid Stainless Steel)

- Hardened and Ground Bushes

- On the nose, slit type plate lock up system

- Manually operated or Motorized running circumferential register (RCR) on one plate cylinder

- Sock dampening / Contactless brushmist dampening system

- Manual / Pneumatic on/off

- Infra red/electro mechanical web break detectors

- Safety guards

- PCB card for dampener motor speed control

- Bustle Wheel Assembly to minimize fan out

- Main Drive Shaft with Balancing Bearing in centre

- Provisions for printing 2 colours on same side of web (direct printing)

- Stainless steel, dynamically-balanced main impression cylinder (in 3-Colour Satellite)

- T Bar blanket lock up for blanket cylinders (Narrow Gap as optional) Manually operated or Motorized lateral register system for both plate cylinders, on the run

- Provision for printing 3 colours on one side of web or 2 colours on one side and 1 colours on other side of web (direct printing) (in 3-Colour Satellite)

- Heavy-duty compensator on 3-Colour Satellite

- Provision for printing 4 colours on both sides of one web, or 2 colours on both sides of two webs, or single colour on both sides of three webs (in 4Hi Tower)

- Heavy-duty timer belt drive for 4 stack units (in 4Hi Tower)

Newspaper Printing machine Folding Unit

- 1:2 Jaw Type Half (½) page Folder( For STAR-16 & STAR-30 Models )

- 2:2 Jaw Type Half (½) page Folder( For newssprint Model ) suitable for 6 webs of Broadsheet / Tabloid size format

- Dynamically balanced R.T.F. Roller, Cutting Cylinder & Jaw Cylinder

- Air former

- Double nipping

- Folder jam switch

- Signal light on the folder

- Main drive shaft with Thomas coupling at cylinder height for minimum backlash and smooth power transmission

- Electronic copy counter

- Adjustable kicker for batches between 10 to 99

- Centralised oil pressure lubrication for drive gears

- Enclosures on Non Loading Side & Operating Side of the Folder

Web Offset Press Optional Features

- Quarter Page Folder (1/4) for maximum 2 webs to run at a maximum speed of

- 22,000 copies per hour

- Double Parallel Folder with or without Cross Perforator (Available in STAR-30 Model only)

- Web under lead system

- Face Clutch on drive side of folder

- Slitter or perforator on nipping rollers

- Upper Former

Reel Stand

- Floor Mounted independent Reel Stand with Wooden Block Brake

Optional Features

- Closed Loop Tension Control System

- Pneumatic Disc Brake & Pneumatic Reel Lifter

- Web Aligner

Web Offset Press’s Auxiliary Equipment

- Automatic Flying Splicer / Zero Speed Splicer

- Automatic Colour to Colour Register Control

- UV Drying System

- Remote Inking System

- Spray Dampening System

- Turner Bar

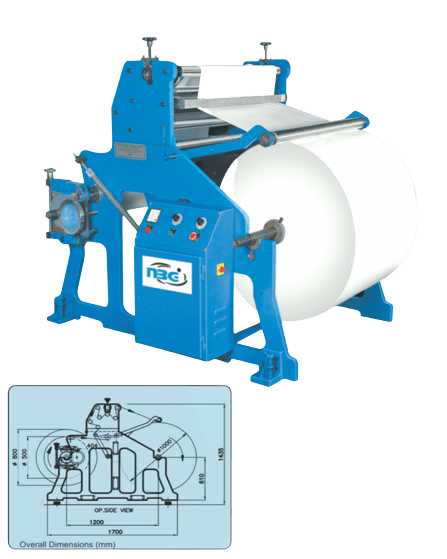

ADD-ON SHEETER ( Model : AOS-900 )

| Technical Specifications * | |

| Substrate | News Print |

| Thickness/GSM | 40-100 GSM |

| Max. Paper Roll Width/Deckle | 889mm |

| Type of Cutting | Simplex Cross Cutting (Scissor Type) with Dead & Fly knife |

| Cut off Length | As per cut off machine |

| Unwind Reel Core Dia | 76 mm(3″) |

| Knife Load max | 100 gsm |

| Cutting Accuracy | 0.5 mm |

| Speed | 140 cuts/min to 160 cuts/min |

| Pile Height | 700 mm |

SLITTER REWINDER ( Model : SR-900 )

| Technical Specifications * | |

| Substrate | Writing Paper & News Prints |

| Thickness/GSM | Max. 150 GSM, Min. 40 GSM |

| Max. Paper Roll Width/Deckle | 914 mm |

| Max. Paper Roll/Deckle Dia | 1067 mm |

| Unwind Reel Core Dia | 76 mm(3″) |

| Speed | 300 MPM |

| Speed | AC Motor |

| Drive | VFD |

[wptabs id=”1555″]

Similar Web Offset Press

What our client say

Ravi Bhardwaj (MD)

Action India Jan Jagran Group - Delhi/Chandigarh

Action India Jan Jagran Group - Delhi/Chandigarh

Our enduring partnership with NBG Printographic has been characterized by unwavering dependability, a steadfast commitment to on-time delivery, and responsive service support. As newspaper publishers, precision and adherence to schedules are paramount, and NBG's web offset newspaper printing machines have consistently met these critical demands. Their service team's rapid response has been an indispensable aspect of our long-term collaboration.

G. Senthil Kumar (Partner)

Bhagyam Printers & Binders - Banglore/Karnataka

Bhagyam Printers & Binders - Banglore/Karnataka

In the realm of textbook printing, precision and steadfastness are non-negotiable. NBG Printographic's web offset technology has consistently met our rigorous quality standards. What sets them apart is their unwavering dedication to swift service support. Their team's quick response time has been a pivotal factor in our enduring partnership.

Yogesh Jaiman (Editor-in-Chief)

Rajasthan Statement - Jaipur/Rajasthan

Rajasthan Statement - Jaipur/Rajasthan

NBG Printographic has been a trusted ally in the newspaper publishing sector. Their web offset newspaper printing machines unfailingly meet our requirements, providing us with the assurance we need to keep our operations running smoothly. The timeliness of their service support has been a cornerstone of our collaboration

Ananta Baishya, (Partner)

Baju Associate & Multicolor Offset Press - Guwahti/Assam

Baju Associate & Multicolor Offset Press - Guwahti/Assam

In the textbook printing domain, predictability and steadfastness are paramount. NBG Printographic's web offset printing machines consistently yield high-quality textbooks, and their dependability has proven to be an asset. Equally vital is the promptness of their service support, which has played a pivotal role in our operational efficiency

Shiv Kumar, (Partner)

Web offset newspaper printing machines

Web offset newspaper printing machines

Our focus has always been on dependability and consistent delivery. NBG Printographic's web offset printing machines have consistently met these requirements, enabling us to meet tight deadlines while maintaining print quality. The punctuality of their service team's assistance has been a vital component of our collaboration